Inside the Boiler

Access to the inside of the boiler is gained through the dome cover opening.

The Dunalastair boiler has four longitudinal stays which connect the smokebox

tubeplate with the firebox throatplate. By good fortune (or clever design) these

are pitched far enough apart that they can be sprung slightly to allow a person

of average size to slide through and get into the boiler barrel. The pictures

below show what the inside looks like.

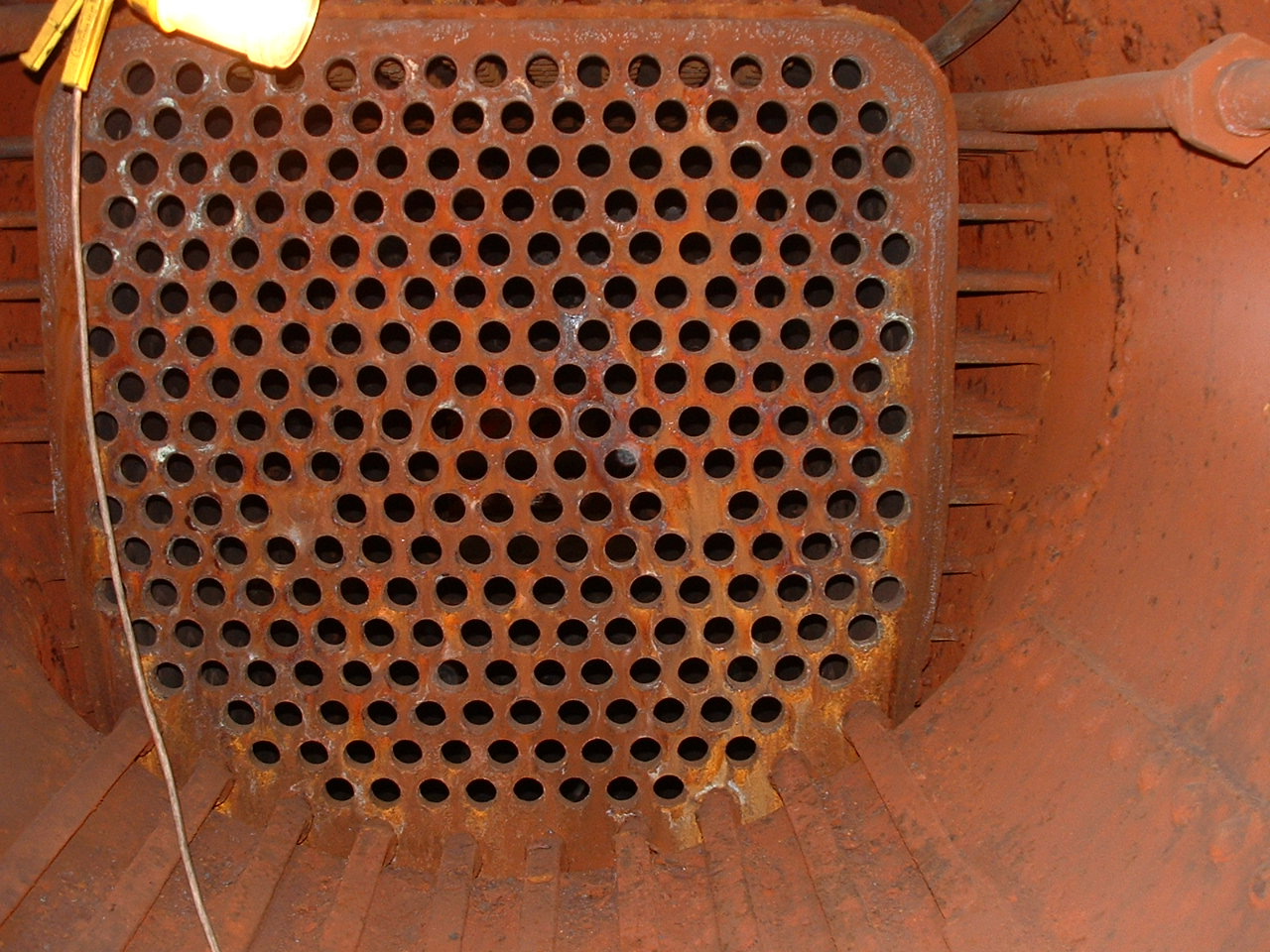

In this picture we are looking from the middle

of the barrel towards the firebox throatplate. The 'honeycomb' structure is the

inner firebox throatplate. The holes are normally filled by the boiler tubes.

The inner firebox is made of copper plate and is attached to the outer firebox

by a series of 'stays'. Some of the sidestays can be seen on either side of the

picture. The ten palmstays can be seen in the bottom of the picture.

Approximately one third of the way up the right hand side of the picture the

line of rivets marking the top edge of the 'doubler plate' can be seen.

In this picture we are looking along the top of the inner

firebox. The vertical bars are the firebox roofstays which connect the outer

firebox and the roof of the inner firebox. The stays are a combination of

'sling' stays which allow a certain amount of flexibility and 'direct' stays

which are more rigid.

.JPG)

This picture shows an identification number

stamped into the inner firebox. The number (57642) belongs to a locomotive in

the same class as 828. So has our engine been running with the inner firebox

from a long-scrapped classmate or is it a works part number?

Here

we see the front end of the boiler from inside the barrel. In this picture we

can see the smokebox tubeplate and the complex system of staying used by JF

McIntosh in the Dunalastair boiler. In the centre are the four longitudinal

stays which connect the smokebox tubeplate and the firebox outer wrapper

backhead. The side

and top stays which connect the smokebox tubeplate directly to the boiler barrel

can be also be seen. It is interesting to see that the connections are made by

'pin and clevis' joints which allow a great deal of flexibility and undoubtedly

reduce the stresses experienced by the boiler during heating and cooling.